If you’re diving into the world of solar panels, you’ve probably come across the term “MC4 Connector.” These little components play a massive role in making sure your solar system works efficiently and safely. So, let’s break down what MC4 connectors are, why they’re important, and how you can handle them like a pro.

Table of Contents

What Are MC4 Connectors?

MC4 connectors, short for “Multi-Contact, 4 millimeters,” are single-contact electrical connectors commonly used for connecting solar panels. They are designed to allow strings of panels to be easily constructed by pushing the compatible connectors from adjacent panels together by hand.

However, they require a tool to disconnect them, ensuring they do not accidentally disconnect when the cables are pulled.

Key Features and Specifications

These connectors are pretty impressive. They’re usually made of copper with tin plating, rated for 30A current and a maximum voltage of 1500V DC.

The insulation material is typically PC/PA, which can withstand temperatures ranging from -40°C to +90°C. As well as, they boast a waterproof degree of IP67, meaning they’re pretty robust against environmental factors.

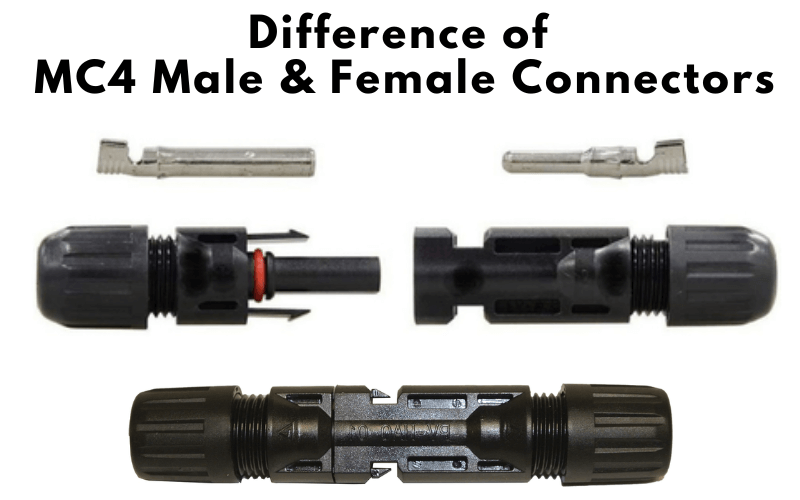

Sometimes, the female and male connectors can be a bit confusing. Here we have an exploded view of a typical MC4 connector. On the right-hand side, the plastic body looks like a male connection, and on the left-hand side, we have a plastic body that looks like a female.

But we actually call them the other way around because we focus on the metal parts. If you look inside, you’ll see that on the right-hand side, the connector has a receiving metal connector, and on the left-hand side, all the way in there, it has a protruding metal connector.

So, the right-hand side metal will slide into the right-hand side connector. Focus on the metal parts to determine which one is male or female. The right-hand side is the female connector, the one with the locking clips, and the left-hand side is the male connector.

Understanding the Safety Mechanisms of MC4 Connectors

Safety is crucial when dealing with high-voltage DC systems, and MC4 connectors are designed with this in mind. They prevent accidental electrical shocks, short circuits, and other hazards.

The connectors feature a secure locking mechanism that ensures they won’t accidentally disconnect, reducing the risk of live wire contact. The insulation material and waterproof design also protect against moisture and other environmental factors that could lead to electrical faults.

How to Connect MC4 Connectors

The beauty of these connectors is that as you are connecting them, the two pins lock in place, preventing the connectors from coming apart. If, by accident, somebody pulls a little on the wire or there’s some tension on it, these clips prevent the connectors from disconnecting.

Ensure that you really hear the click sound, when you are connecting the MC4 male to the female. Sometimes you have to push a little harder to get that rubber seal to completely seal, and only then do both clips need to clip. Make sure they are fully in and completely locked in place.

When connected correctly, they maintain a tight fit that minimizes power losses and potential system failures.

Tools You Need for Installing MC4 Connectors

These connectors are not rocket science, but it is really important that the wire has a proper connection with the metal part of the connector. I want to show you a specific tool that can really help ensure this connection is properly made.

To ensure you’re installing these connectors safely and correctly, you’ll need a few essential tools:

MC4 Disconnect Tool Kit: These specialized tools are recommended for safely disconnecting and tightening MC4 connectors. They help ensure the connectors are properly secured without causing damage.

MC4 Crimping Tool: A proper crimping tool is crucial for a secure and safe connection. It ensures the cable is crimped onto the MC4 connector correctly, meeting UL standards.

The reason I want to show you this is that when you are connecting the metal part to the wire, please don’t use a normal plier. Instead of just clamping the wire between the metal bits, you want to squeeze and kind of wrap it around. You want to ensure that the connection is proper.

I’ve seen many systems with vague complaints about performance, and finally, it turned out the connection between the wire and the metal bit was improperly squeezed and not held in place. It started to corrode over time, increasing resistance. You can avoid a bad connection by using a crimping tool to really squeeze around the wire.

MC4 Crimping Tool Kit

- Disconnector tool

- Connector Set

- Crimping tool

- wire stripper

Wire Strippers: Necessary for preparing the cable by stripping the insulation to the correct length before crimping the connector.

Best Practices for Handling MC4 Connectors

When dealing with MC4 connectors, following best practices ensures both safety and efficiency:

Proper Handling: Handle MC4 connectors with care to avoid damaging the components or breaking the watertight seal. Apply gentle force when connecting and disconnecting to prevent accidental disconnections.

Safety Precautions: Always wear appropriate PPE and use insulated tools. This reduces the risk of injury and ensures electrical safety.

Environmental Conditions: Avoid working with connectors in extreme temperatures or during precipitation to prevent moisture ingress and other hazards.

Maintenance and Inspection: Regularly inspect MC4 connectors for signs of wear, damage, or corrosion. Replace any compromised connectors to maintain optimal performance and safety.

Inspecting MC4 Connectors for Wear and Tear

Regular inspections are crucial for ensuring the longevity and safety of your solar panel system. Look out for visible cracks, loose terminals, corrosion, moisture intrusion, dirt buildup, and wear.

A sampling approach is often recommended, inspecting a small percentage of the total connectors on-site regularly, especially in commercial and industrial installations.

Alternatives to MC4 Connectors

While MC4 connectors are widely used, there are alternatives like T4 connectors, SolarLok connectors, and Anderson Power Pole connectors. Each offers varying levels of compatibility, durability, and ease of use, so it’s essential to consider your specific system requirements and environmental conditions when choosing an alternative.

Final Thoughts

MC4 connectors might seem like small components, but they play a vital role in ensuring the efficiency and safety of your solar panel system. By understanding their importance, using the right tools, and following best practices, you can ensure your solar installation is both safe and effective. Remember, a secure connection today can save you from a lot of trouble down the line. So, handle your MC4 connectors with care, and happy solar installing!